Most widely used bearing type and particularly versatile. They create less friction torque than other types of bearings and are optimized for low noise and low vibration which enables high rotational speeds.

Have a spherical raceway in the outer ring with a centre of curvature matched with the bearing centre. This allows the inner ring, balls, and cage to rotate freely around the bearing centre, maintaining alignment.

Advantages: generate less friction than any other type of rolling bearing, which enables them to run cooler even at high speeds. Because of low heat generation, the bearing temperature is lower, leading to extended bearing life and maintenance intervals.

They minimize friction and reduce noise and vibration during operation. The barrel-shaped spherical rollers reduce friction within the bearing and allow the bearing to accommodate angular misalignment

Advantages: offer an excellent service life combined with high levels of reliability.

Designed for rotary motion that use needle-shaped thin rollers as rolling elements and have low sectional height and large load capacity. They help save space by making the whole machine compact. They are widely used in range of products such as automobiles, motorcycles, printing machines, industrial robots and construction machinery.

Advantages: smaller sized and light weight with a large load capacity. They resist damage from fatigue, shock and edge loads, and they tolerate misalignment better than rolling element bearings.

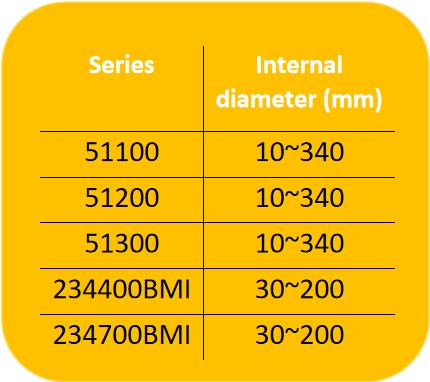

Designed to allow rotation between moving parts; they are specially engineered to accommodate high axial loads – loads parallel to the shaft.

They are used in vehicles to support axial forces caused by helical gears in modern vehicle gearboxes. They are also ideal for higher speed automotive applications that require oil lubrication.

Advantages: being an axial bearing, permits rotation between parts. Thrust bearings support the axial thrust of both horizontal and vertical shafts. Therefore, they can prevent the shaft from drifting in the axial direction and to transfer thrust loads applied on the shaft.

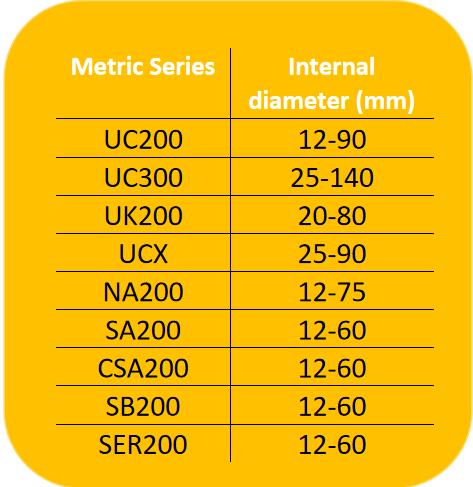

Standard radial bearings that have been adapted to fit into a housing, which is why they are often referred to as adapted radial bearings. While they are commonly sold with a housing, they can also be purchased without one.

Advantages: The different locking methods enable quick and easy mounting of insert bearings onto the shaft. Accommodate initial misalignment. Long service life. Reduced noise and vibration levels.

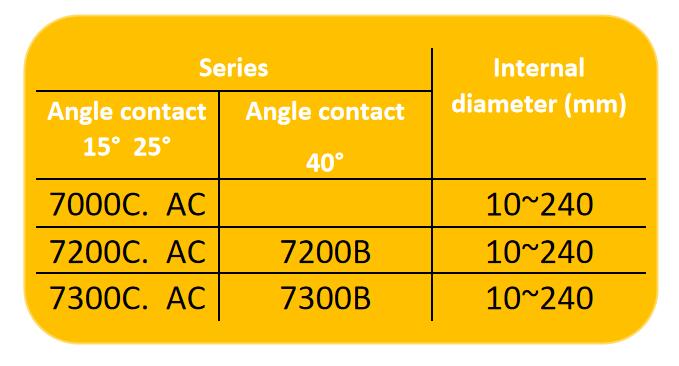

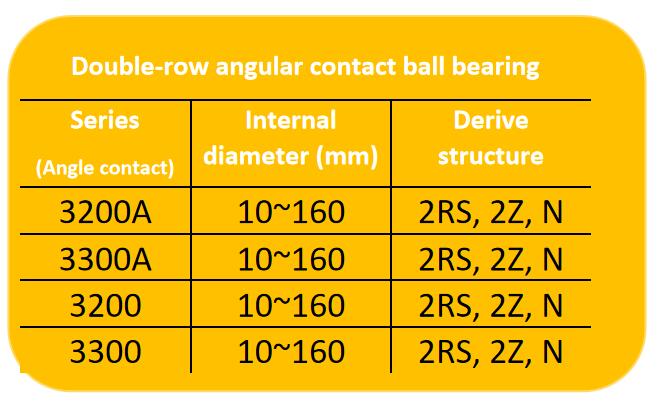

Designed to support axial loads in both directions and have a high load carrying capacity.

They can support a limited radial load for a given axial load, use less axial space than double row bearings and are separable.

Advantages: High axial load carrying capacity in one direction. The have a radial load carrying capacity with high-speed capacity. They are also low maintenance and low heat generation. Low noise levels

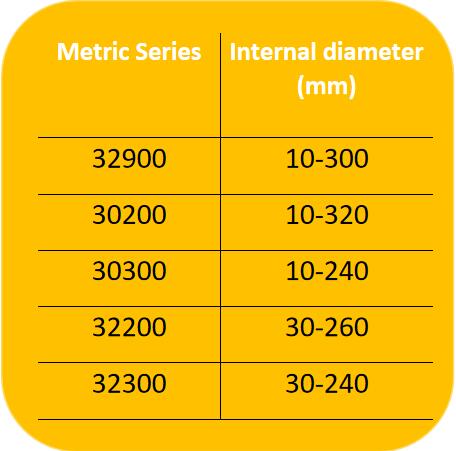

A tapered roller bearing is specially designed and constructed to manage both radial and thrust forces on the rotating shafts and housings of machine tools. The plain cup tapered roller bearing contains a single row of bearings and is suited to applications with light or medium loads.

They are commonly used for moderate speed, heavy duty applications where durability is required.

Advantages: cost-effective and simple solution with easy and accurate installation

We’d love to hear from you. Please contact to our sales team, and see how we can help you.